Tel:+86-0512-65488442

Contact:Mr.Wang

Mobile:15821686068

Email:Sale@bluesky-tech.cn

Fax:+86-0512-65488442

Zip code:215131

URL:www.bluesky-tech.cn

Address:Xiangcheng District Huangqiao Dazhuang village of Suzhou city in Jiangsu Province

| The MIM technology advantage Update time 2016-8-23 9:07:54 Click times 836 次 Return |

||||||||||||||||||||||||||||||||||||||||||||||||||||

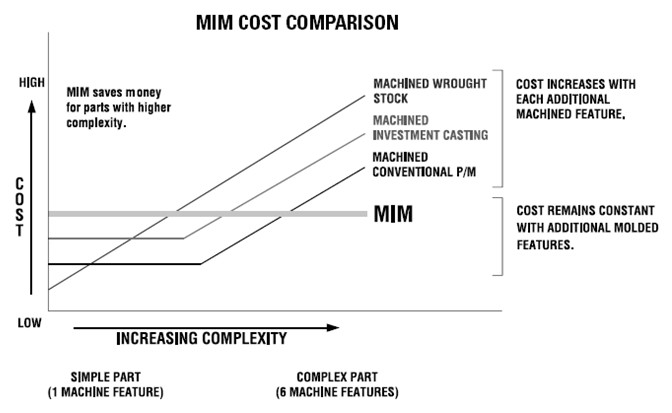

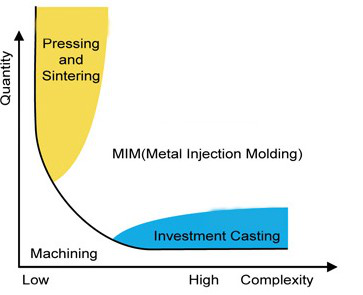

• MIM can produce geometries that eliminate secondary operations • MIM offers superior density, corrosion performance, strength, ductility • MIM can combine two or more PM components into one, reducing part count MIM vs. Machining • MIM designs save material and weight • MIM provides cost savings through better material utilization—sprues and runners can be reground and reused as feedstock with no compromise to final properties • Molding from a single tool eliminates multiple set-up operations • Difficult-to-machine materials can be molded into a net shape MIM vs. Investment Casting • MIM can produce thinner wall sections, sharper cutting points • MIM produces better surface finish • MIM is better for small-diameter blind and through holes • MIM greatly reduces requirements for finish machining • MIM produces high volumes of small components at a lower cost, faster lead times |

||||||||||||||||||||||||||||||||||||||||||||||||||||

Tel:

Tel: