Technological

Contact us

Suzhou Bluesky New material Technology Co., Ltd.

Tel:+86-0512-65488442

Contact:Mr.Wang

Mobile:15821686068

Email:Sale@bluesky-tech.cn

Fax:+86-0512-65488442

Zip code:215131

URL:www.bluesky-tech.cn

Address:Xiangcheng District Huangqiao Dazhuang village of Suzhou city in Jiangsu Province

Tel:+86-0512-65488442

Contact:Mr.Wang

Mobile:15821686068

Email:Sale@bluesky-tech.cn

Fax:+86-0512-65488442

Zip code:215131

URL:www.bluesky-tech.cn

Address:Xiangcheng District Huangqiao Dazhuang village of Suzhou city in Jiangsu Province

Your current position:Home > TechnologicalTechnological

| The MIM application Update time 2016-8-23 9:07:30 Click times 832 次 Return |

||

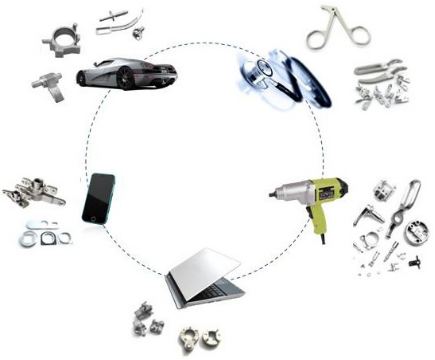

MIM Application Products which have following features fit for MIM technical. Complex-shape Just like injection molding, MIM can design 3D shape freely. As a molding process, additional shape will not bring extra costs. If you want to save weight through shape design, then the cost will reduce too. So MIM is a ideal way of assembling one or more part into multi-function components. The design rule of MIM is very similar with injection molding, and thus easily adapt to 3D complex-shape metal parts. Precision size Usually, MIM near net shaping accuracy is ±0.5% of the established size, even though some of the size characteristics can reach ±0.3%. Just as the other technical, high precision means a higher cost, so if it can satisfy the use we suggest that size tolerance can moderate relaxed. The tolerance which MIM cannot directly meet will be realized by subsequent processing. Thin-wall Less than 6mm thickness is more suitable for MIM. Thicker can also, but the cost of process time and materials will increase much. Thin-wall which lower than 0.5mm, can also realize by MIM technical. We even can produce products whose thin-wall is only 0.2mm (It rely on the concrete products shape more or less). Weight & size Choosing MIM will be a wise decision when parts weight is less than 100g, less than 50g is the most common applications. However, parts weight that exceeds 250g can also use MIM to produce .In this case the main cost of MIM comes from raw materials. MIM will make efforts to reduce the weight of components in the early stage of product design. Like plastic products, MIM can not only use the core and the stent to reduce components weight but also would not affect the product integrity. MIM in small and micro parts stands out, even the weight is less than 0.1g and the length is over 250mm can be done too. Mass- production For MIM parts, mould and early product development process is necessary. So, it will influence the decision-making process if the minimum is below thousands of pieces per year. MIM can easily make it come true that from a small production to ascend to the millions of pieces by economy way. Now, we have been done many kinds of dozens million demands MIM products. Wide materials Wide materials MIM can deal many kinds of materials, such as ferroalloy, stainless steel, copper, KOVAR, high temperature alloy, hard alloy and so on. Design support Bluesky New material provide full services net work to our customer from product design , material selection upgrade, product development, small batch to mass production. |

Tel:

Tel: